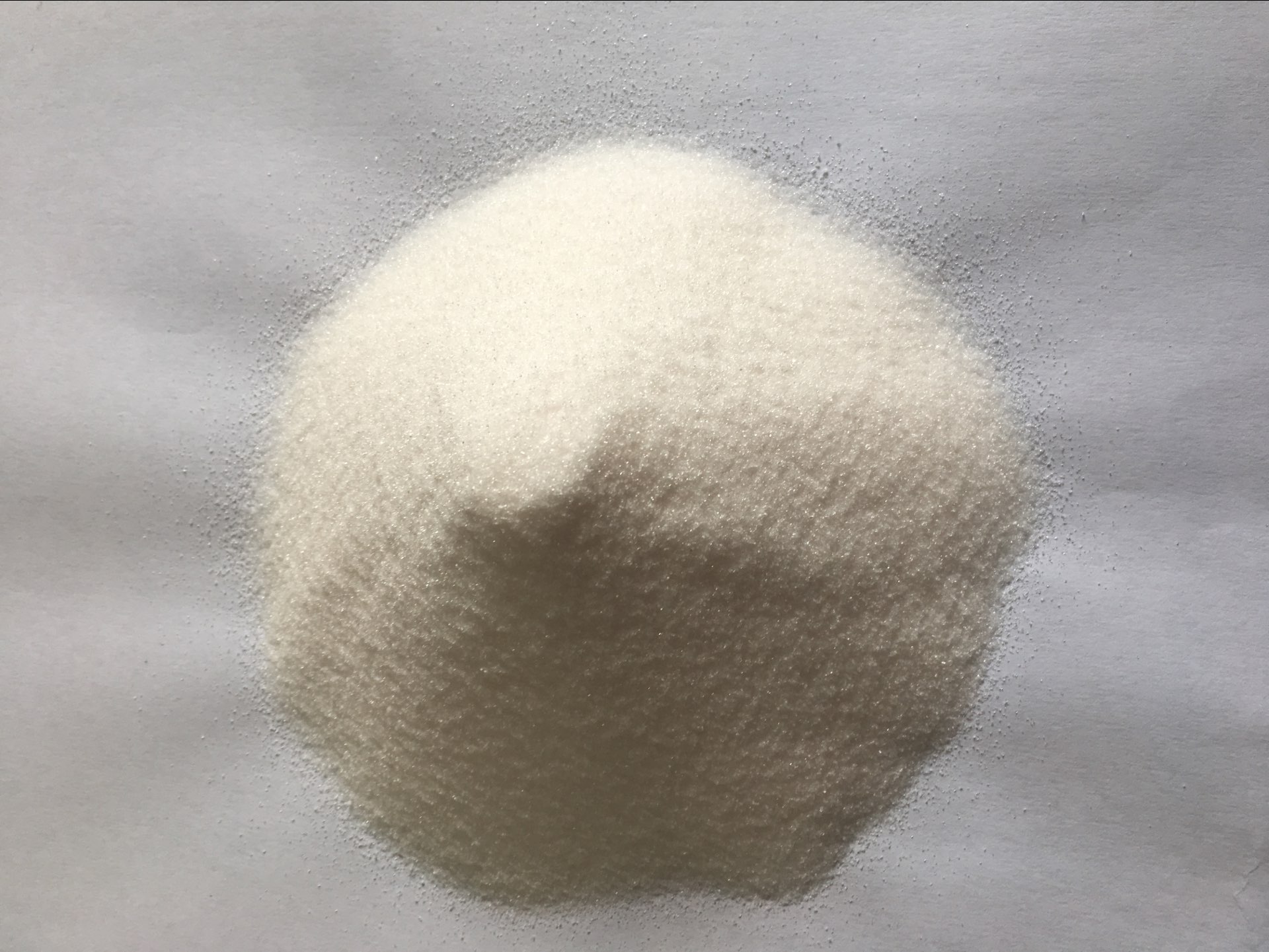

Welcome to the realm of sodium polyacrylate food, where science meets culinary innovation. This versatile ingredient, with its unique properties, is transforming the food industry, enhancing food quality and creating new culinary possibilities.

Sodium polyacrylate, a superabsorbent polymer, has found its niche in the food industry as a thickener and stabilizer, playing a crucial role in shaping the texture, viscosity, and mouthfeel of various food products.

Safety and Regulatory Considerations

Sodium polyacrylate is generally considered safe for human consumption in small amounts as a food additive. However, like all food additives, it is subject to regulatory limits and guidelines to ensure its safety and proper use.

Regulatory Limits and Guidelines, Sodium polyacrylate food

- In the United States, the Food and Drug Administration (FDA) has established a maximum allowable level of 0.1% sodium polyacrylate in dry beverage mixes.

- The European Food Safety Authority (EFSA) has established an Acceptable Daily Intake (ADI) of 0-5 mg/kg body weight per day for sodium polyacrylate.

- Other regulatory agencies, such as Health Canada and the Australian Food Standards Code, have also established similar limits and guidelines for sodium polyacrylate use in food.

Potential Health Concerns and Limitations

While sodium polyacrylate is generally safe for consumption in small amounts, excessive intake may cause potential health concerns, such as:

- Gastrointestinal Distress:High doses of sodium polyacrylate can cause gastrointestinal discomfort, including nausea, vomiting, and diarrhea.

- Dehydration:Sodium polyacrylate has a high water-holding capacity, and excessive consumption can lead to dehydration if not accompanied by adequate fluid intake.

- Interaction with Medications:Sodium polyacrylate can potentially interfere with the absorption of certain medications, particularly those that are taken orally.

It is important to adhere to recommended usage levels and follow manufacturer’s instructions when consuming food products containing sodium polyacrylate.

Alternatives to Sodium Polyacrylate: Sodium Polyacrylate Food

Sodium polyacrylate is a versatile thickener and stabilizer used in various food applications. However, concerns regarding its safety and potential health effects have prompted the exploration of alternative ingredients that can provide similar functionalities without compromising consumer safety.

Several alternative thickeners and stabilizers are available, each with unique properties and applications. These alternatives can be derived from natural sources, such as plants or microorganisms, or can be synthetically produced. The choice of alternative depends on the specific requirements of the food product, including desired texture, stability, and shelf life.

Natural Alternatives

- Xanthan Gum:A polysaccharide derived from bacteria, xanthan gum is a versatile thickener and stabilizer that can be used in a wide range of food products, including sauces, dressings, and baked goods. It provides a viscous, gel-like texture and helps prevent syneresis (water separation).

- Guar Gum:Another polysaccharide derived from plants, guar gum is a highly viscous thickener that is commonly used in gluten-free baking and as a stabilizer in ice cream and dairy products. It can also be used to improve the texture of sauces and gravies.

- Locust Bean Gum:A galactomannan derived from the seeds of the carob tree, locust bean gum is a thickener and stabilizer that is similar to guar gum. It is often used in combination with other hydrocolloids to create desired textures in food products.

Synthetic Alternatives

- Carboxymethyl Cellulose (CMC):A cellulose derivative, CMC is a thickener and stabilizer that is commonly used in sauces, dressings, and baked goods. It provides a smooth, creamy texture and helps prevent syneresis.

- Hydroxypropyl Methylcellulose (HPMC):Another cellulose derivative, HPMC is a thickener and stabilizer that is often used in dairy products, sauces, and gravies. It can also be used as a film-forming agent to prevent moisture loss in food products.

- Sodium Alginate:A polysaccharide derived from brown algae, sodium alginate is a thickener and stabilizer that is commonly used in ice cream, dairy products, and processed meats. It can also be used to create gels and foams.

Advantages and Disadvantages of Using Alternatives

The use of alternatives to sodium polyacrylate offers several advantages, including improved safety, natural ingredients, and potential cost savings. However, there are also some disadvantages to consider, such as potential differences in texture and functionality, as well as the need for careful selection and formulation to achieve desired results.

Future Trends and Innovations

The food industry is constantly evolving, and sodium polyacrylate is expected to play an increasingly important role in this evolution. As research continues and new applications are discovered, this versatile ingredient is poised to revolutionize the way we produce, package, and consume food.

Emerging Applications

One of the most exciting areas of research is the use of sodium polyacrylate as a fat replacer. This ingredient can mimic the texture and mouthfeel of fat, making it an ideal substitute for high-calorie ingredients in a wide range of products, from baked goods to processed meats.

Sodium polyacrylate is also being explored as a way to improve the shelf life of food products. By absorbing moisture and preventing spoilage, this ingredient can help to extend the shelf life of perishable items, reducing waste and saving consumers money.

Ongoing Research and Advancements

Researchers are also exploring the use of sodium polyacrylate in novel food packaging applications. This ingredient can be used to create edible films and coatings that protect food from spoilage and extend its shelf life. These films can also be used to incorporate functional ingredients into food products, such as antioxidants or probiotics.

Another area of active research is the use of sodium polyacrylate in food processing. This ingredient can be used to improve the texture and quality of food products, such as by reducing syneresis in yogurt or improving the texture of processed meats.

Potential Future Developments

As research continues, it is likely that even more innovative applications for sodium polyacrylate will be discovered. This ingredient has the potential to revolutionize the food industry, making it more efficient, sustainable, and nutritious.

FAQ Section

Is sodium polyacrylate safe for human consumption?

Yes, sodium polyacrylate is generally recognized as safe (GRAS) for use in food by regulatory authorities such as the US Food and Drug Administration (FDA) and the European Food Safety Authority (EFSA).

What are some examples of foods that contain sodium polyacrylate?

Sodium polyacrylate can be found in a variety of food products, including sauces, dressings, dairy products, processed meats, and even pet food.

Are there any alternatives to sodium polyacrylate?

Yes, there are several alternatives to sodium polyacrylate that can be used as thickeners and stabilizers in food, such as xanthan gum, guar gum, and locust bean gum.