Food grade water hoses play a crucial role in various industries, ensuring the safe and hygienic transfer of liquids intended for human consumption. These specialized hoses are meticulously designed and constructed to meet stringent food safety standards, guaranteeing the purity and integrity of the conveyed liquids.

Their versatility extends to a wide range of applications, from food processing and beverage dispensing to pharmaceutical manufacturing. By understanding the materials, design, and applications of food grade water hoses, you can make informed decisions to safeguard your operations and maintain the highest levels of hygiene.

Food Grade Water Hose Overview

Food grade water hoses are specialized hoses designed to safely transport water intended for human consumption or use in food processing. These hoses are manufactured using materials that meet strict regulatory standards, ensuring the water’s quality and preventing contamination.

Food grade water hoses are characterized by their durability, flexibility, and resistance to chemicals and microorganisms. They are typically made from materials such as polyethylene, polyurethane, or rubber that are FDA-approved for food contact. These hoses are also designed to withstand high temperatures and pressures, making them suitable for a variety of applications.

Industries Using Food Grade Water Hoses

Food grade water hoses are commonly used in various industries where maintaining water quality is crucial, including:

- Food and beverage processing

- Pharmaceutical manufacturing

- Water treatment facilities

- Hospitals and healthcare facilities

- Dairy and livestock operations

Material Composition and Standards

Food grade water hoses are constructed using a range of materials that comply with strict food safety regulations. These materials must be non-toxic, odorless, and tasteless to ensure the purity of the water passing through them.

Materials Used

- PVC (Polyvinyl Chloride):A durable and flexible material commonly used in food grade hoses due to its resistance to chemicals and wear.

- Polyurethane:A lightweight and highly flexible material that provides excellent resistance to abrasion and kinking.

- Rubber:A natural or synthetic material that offers good flexibility and resistance to heat and chemicals.

Food Safety Standards

Food grade water hoses must adhere to stringent food safety standards to ensure the water they transport is safe for consumption. These standards include:

- FDA (Food and Drug Administration):Regulates the safety of food contact materials in the United States.

- NSF (National Sanitation Foundation):An independent organization that sets standards for food safety equipment and materials.

Meeting these standards ensures that the materials used in food grade water hoses do not leach harmful substances into the water, maintaining its quality and safety.

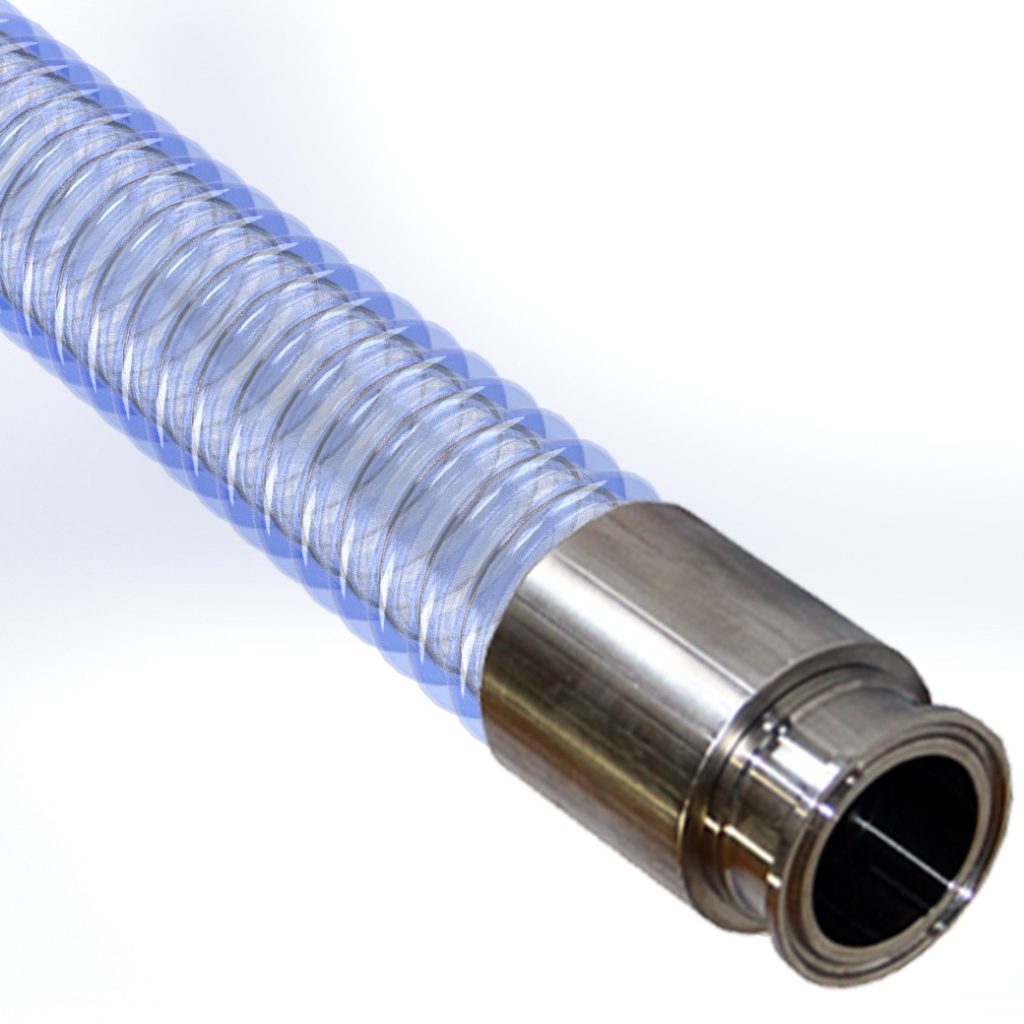

Design and Construction: Food Grade Water Hose

Food grade water hoses are engineered to meet the unique requirements of the food and beverage industry, ensuring the safe and sanitary transfer of liquids. They typically comprise several layers, each serving a specific function.

Reinforcement Layers

The inner core of the hose is made of a flexible, non-toxic material such as EPDM (ethylene propylene diene monomer) or PVC (polyvinyl chloride). To enhance durability and prevent kinking, multiple layers of reinforcement are added. These layers may be made of synthetic fibers like polyester or aramid, providing strength and resistance to pressure and abrasion.

Fittings and End Connections, Food grade water hose

The ends of the hose are equipped with fittings or end connections, which allow for secure attachment to equipment or piping systems. Common fittings include threaded couplings, quick-connect couplings, and camlock fittings. These fittings are typically made of stainless steel or other food-grade materials to prevent contamination and ensure a tight seal.

Flexibility, Durability, and Pressure Resistance

Flexibility is crucial for food grade water hoses, enabling them to navigate tight spaces and bends during installation and operation. Durability ensures the hose can withstand repeated use and harsh cleaning practices. Pressure resistance is essential to prevent bursts or leaks, especially when the hose is subjected to high-pressure systems.

Applications and Considerations

Food grade water hoses are essential in various industries where the transportation of clean, potable water is crucial for maintaining hygiene and product quality.

Specific applications include:

- Food processing:Conveying water for cleaning, rinsing, and processing food products.

- Beverage dispensing:Transferring water to beverage dispensers, fountains, and bottling lines.

- Pharmaceutical manufacturing:Supplying water for cleaning, sterilization, and production processes.

Factors to Consider

Selecting the right food grade water hose requires careful consideration of several factors:

- Temperature range:Hoses should withstand the temperature range encountered during use, ensuring compatibility with hot or cold water.

- Chemical compatibility:Hoses must be resistant to chemicals used in cleaning and sanitizing processes.

- Cleaning requirements:Hoses should be easy to clean and sanitize to prevent bacterial growth and contamination.

- Pressure rating:Hoses must withstand the pressure generated in the water system.

- Flexibility and durability:Hoses should be flexible for easy handling and durable to withstand repeated use.

Maintenance and Inspection

Proper maintenance and inspection of food grade water hoses are crucial to ensure hygiene and safety in food processing and handling operations. Regular cleaning, sanitizing, and storage practices help prevent the accumulation of bacteria, mold, or other contaminants that could compromise the quality and safety of food products.

Cleaning

- Clean food grade water hoses thoroughly after each use to remove food residues, dirt, and other contaminants.

- Use warm water and a mild detergent specifically designed for food contact surfaces.

- Rinse hoses thoroughly with clean water to remove any detergent residue.

Sanitizing

- Sanitize food grade water hoses regularly to eliminate bacteria and other microorganisms.

- Use a food-grade sanitizer according to the manufacturer’s instructions.

- Allow the sanitizer to remain in contact with the hose for the recommended dwell time.

Storage

- Store food grade water hoses in a clean, dry, and well-ventilated area.

- Keep hoses away from direct sunlight and extreme temperatures.

- Avoid storing hoses in areas where they may come into contact with chemicals or other contaminants.

Regulations and Compliance

Food grade water hoses must comply with stringent regulations and industry standards to ensure the safety and quality of food products. These regulations aim to prevent contamination and maintain hygiene throughout the food handling process.

The primary regulatory bodies governing food grade water hoses include:

- Food and Drug Administration (FDA):The FDA establishes and enforces regulations for food safety in the United States, including the use of food contact materials such as hoses.

- National Sanitation Foundation (NSF):NSF is an independent organization that develops and certifies standards for food equipment and materials, including water hoses.

- United States Department of Agriculture (USDA):The USDA regulates the meat and poultry industry, and its standards include requirements for food grade water hoses used in meat and poultry processing facilities.

Consequences of Non-Compliance

Non-compliance with food grade water hose regulations can have serious consequences, including:

- Product contamination:Hoses that do not meet food grade standards may leach harmful chemicals or bacteria into food products, posing a health risk to consumers.

- Regulatory penalties:Businesses that use non-compliant hoses may face fines or other penalties from regulatory agencies.

- Loss of reputation:Food safety incidents can damage a company’s reputation and lead to loss of business.

Therefore, it is crucial for businesses to adhere to food grade water hose regulations to ensure the safety of their products and protect their reputation.

Common Queries

What materials are commonly used in food grade water hoses?

Food grade water hoses are typically made from materials such as PVC, polyurethane, and rubber, which comply with food safety regulations and are resistant to chemicals and microbial growth.

How do I ensure the cleanliness of food grade water hoses?

Regular cleaning and sanitizing of food grade water hoses is essential to maintain hygiene. Follow the manufacturer’s instructions for cleaning and use appropriate sanitizing solutions to eliminate bacteria and other contaminants.

What factors should I consider when selecting a food grade water hose?

When selecting a food grade water hose, consider factors such as the temperature range of the liquids being conveyed, chemical compatibility, pressure resistance, and the specific application requirements.