Polysorbate 60 in food is a tale of culinary innovation and scientific precision. This versatile emulsifier enhances our culinary creations, stabilizing textures, preventing separation, and adding a touch of magic to our favorite dishes.

From salad dressings to baked goods, polysorbate 60 plays a crucial role in shaping the flavors and textures we savor.

Polysorbate 60

Polysorbate 60 is a nonionic surfactant, meaning it does not ionize in water, and is widely used in the food industry as an emulsifier and stabilizer. It is a viscous, amber-colored liquid with a slightly bitter taste and a faint odor.

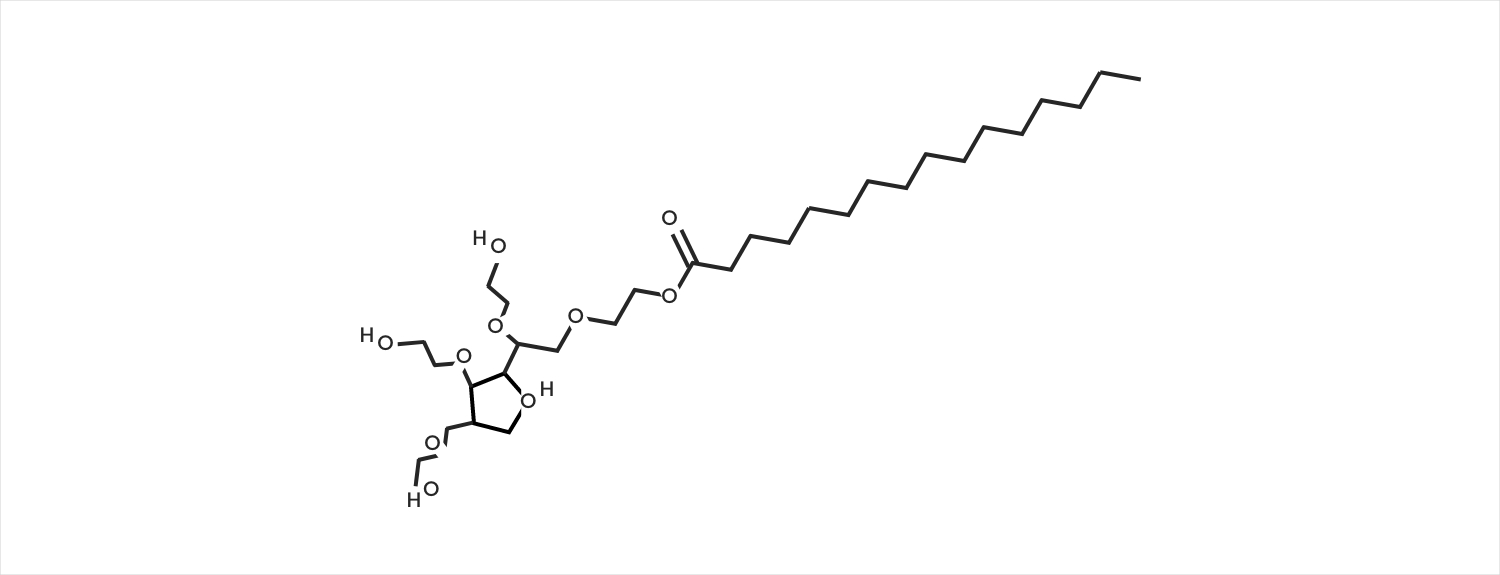

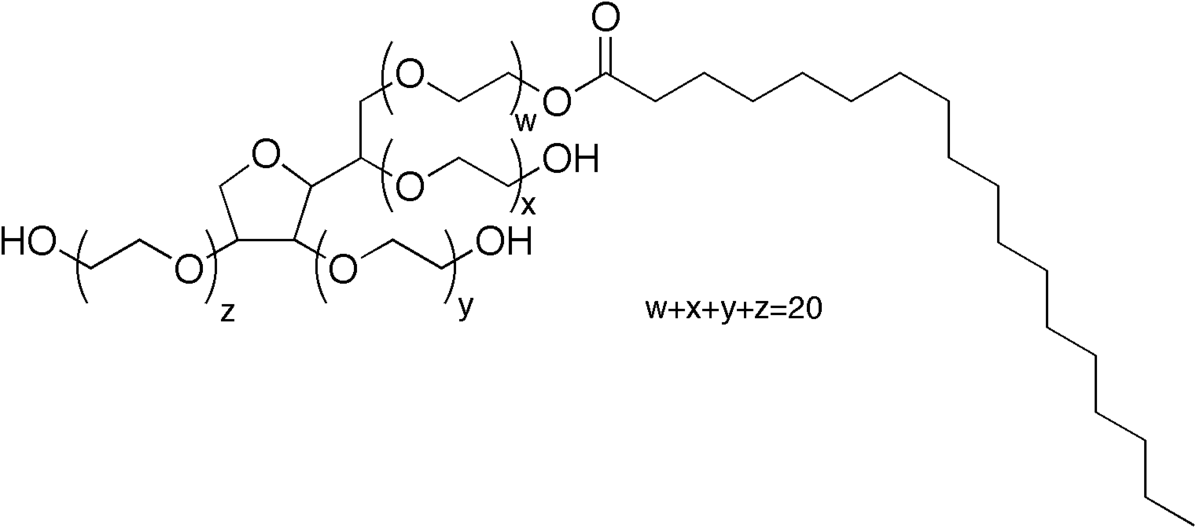

Chemical Structure

Polysorbate 60 is a polyoxyethylene sorbitan monostearate, composed of a hydrophilic polyethylene glycol (PEG) chain and a lipophilic sorbitan monostearate chain. The PEG chain contains an average of 20 ethylene oxide units, while the sorbitan monostearate chain is derived from sorbitol and stearic acid.

The chemical structure of polysorbate 60 can be represented as:

CH3(CH 2) 16COOCH 2CH(OH)CH 2O(CH 2CH 2O) nH

where n represents the average number of ethylene oxide units (approximately 20).

Molecular Weight and Solubility

The molecular weight of polysorbate 60 is approximately 1,200 g/mol. It is soluble in water, alcohol, and other organic solvents.

Other Properties

- HLB (hydrophilic-lipophilic balance) value: 14.9

- Emulsifying properties: Oil-in-water (O/W) emulsifier

- Stabilizing properties: Prevents separation of oil and water phases in emulsions

- Wetting agent: Reduces the surface tension of water, allowing it to spread more easily

- Dispersing agent: Helps disperse solid particles in liquids

Food Applications of Polysorbate 60: Polysorbate 60 In Food

Polysorbate 60 finds extensive use in various food products due to its exceptional properties as an emulsifier, stabilizer, and surfactant. Its ability to prevent phase separation and enhance product stability makes it a valuable additive in a wide range of culinary creations.

Emulsifier

Polysorbate 60 acts as an emulsifier, facilitating the blending of immiscible liquids, such as oil and water. In salad dressings, sauces, and mayonnaise, it ensures a uniform and stable emulsion, preventing the separation of oil and vinegar.

Stabilizer

Polysorbate 60 serves as a stabilizer, inhibiting the formation of crystals and preserving the texture of food products. In ice cream and frozen desserts, it prevents the growth of large ice crystals, resulting in a smoother and creamier texture.

Surfactant

As a surfactant, polysorbate 60 reduces surface tension and promotes wetting. In baking, it aids in the incorporation of air into batters, leading to lighter and fluffier cakes and pastries. In confectionery, it enhances the spreadability of chocolate and other coatings.

Safety and Regulations

Polysorbate 60 has a well-established safety profile, backed by extensive research and usage history in the food industry. Regulatory bodies worldwide, including the US Food and Drug Administration (FDA) and the European Food Safety Authority (EFSA), have deemed it safe for consumption in food products.

Acceptable Daily Intake

The acceptable daily intake (ADI) for polysorbate 60 has been established by the Joint FAO/WHO Expert Committee on Food Additives (JECFA) at 10 mg/kg of body weight. This means that a person weighing 60 kg can safely consume up to 600 mg of polysorbate 60 per day without adverse effects.

Allergic Reactions and Health Concerns

Polysorbate 60 is generally considered non-allergenic, and allergic reactions are rare. However, individuals with sensitivities to other polysorbates or related compounds may experience allergic reactions. These reactions can range from mild skin irritation to more severe respiratory issues.

Some studies have suggested that high levels of polysorbate 60 consumption may be linked to certain health concerns, such as gastrointestinal disturbances, liver damage, and kidney toxicity. However, these concerns are primarily associated with excessive intake beyond recommended levels and are not typically observed in normal dietary consumption.

Production and Manufacturing Process

Polysorbate 60 is industrially produced through a multi-step process involving chemical reactions and purification. The primary raw materials used are sorbitol, ethylene oxide, and lauric acid.

Raw Materials

Sorbitol is a sugar alcohol derived from glucose, while ethylene oxide is a highly reactive gas. Lauric acid is a fatty acid commonly obtained from coconut or palm oil.

Chemical Reactions

In the first step, sorbitol is reacted with ethylene oxide in a process called ethoxylation. This reaction introduces multiple ethylene oxide units to the sorbitol molecule, forming a polyoxyethylene sorbitol intermediate.Next, the polyoxyethylene sorbitol intermediate is reacted with lauric acid in an esterification reaction.

This reaction replaces the hydroxyl groups of the polyoxyethylene sorbitol with lauric acid, resulting in the formation of polysorbate 60.

Purification

After the esterification reaction, the crude polysorbate 60 is purified to remove impurities and excess reactants. This typically involves several steps, including filtration, extraction, and distillation. The purified polysorbate 60 is then concentrated and dried to obtain the final product.

Simplified Flowchart

[Provide a simplified flowchart or diagram to illustrate the production process.]

Alternative Emulsifiers and Surfactants

Polysorbate 60 is a widely used emulsifier and surfactant in the food industry. However, there are several alternative emulsifiers and surfactants that can be used instead of polysorbate 60, each with its unique properties and functionalities.

Factors to consider when selecting an alternative emulsifier or surfactant include its emulsification efficiency, stability, compatibility with other ingredients, and cost. Some common alternatives to polysorbate 60 include:

Mono- and Diglycerides

- Naturally occurring emulsifiers derived from vegetable oils

- Excellent emulsification properties and stability

- Compatible with a wide range of ingredients

- May impart a slightly bitter taste

Lecithin, Polysorbate 60 in food

- Phospholipid emulsifier derived from soybeans or eggs

- Good emulsification properties, especially for oil-in-water emulsions

- Acts as an antioxidant and stabilizer

- May cause allergic reactions in some individuals

Sodium Stearoyl Lactylate (SSL)

- Anionic emulsifier derived from stearic acid and lactic acid

- Excellent emulsification properties and stability, especially for baked goods

- Improves crumb structure and texture

- May interact with calcium and magnesium ions

Xanthan Gum

- Polysaccharide emulsifier and stabilizer

- Forms viscous solutions that help stabilize emulsions

- Provides texture and mouthfeel to food products

- May interact with other hydrocolloids

Case Studies and Applications

Polysorbate 60 has been widely used in various food products, demonstrating its effectiveness as an emulsifier and surfactant. Here are a few case studies and examples of successful applications of polysorbate 60:

Case Study 1: Salad Dressings

Polysorbate 60 is commonly used in salad dressings to prevent oil separation and maintain a smooth, creamy texture. It acts as an emulsifier, helping to stabilize the mixture of oil and water, preventing the dressing from becoming watery or lumpy.

Case Study 2: Ice Cream and Frozen Desserts

In ice cream and frozen desserts, polysorbate 60 is used as a surfactant to improve the texture and prevent ice crystal formation. It helps to create a smooth, creamy consistency and reduces the risk of graininess or iciness in the final product.

Case Study 3: Baked Goods

Polysorbate 60 is also used in baked goods, such as cakes and pastries, to improve the texture and shelf life. It acts as an emulsifier, helping to distribute fats and oils evenly throughout the batter, resulting in a more tender and moist product.

Additionally, it helps to prevent staling and extend the shelf life of baked goods.

Essential Questionnaire

What exactly is polysorbate 60?

Polysorbate 60 is a non-ionic surfactant and emulsifier derived from sorbitol and fatty acids. It is a viscous liquid with a faint odor.

Is polysorbate 60 safe to consume?

Yes, polysorbate 60 is generally recognized as safe (GRAS) by the FDA and other regulatory agencies. It has been extensively tested and found to be safe for use in food products.

What are some common applications of polysorbate 60 in food?

Polysorbate 60 is widely used in salad dressings, mayonnaise, baked goods, ice cream, and other processed foods to improve texture, prevent separation, and enhance flavor.