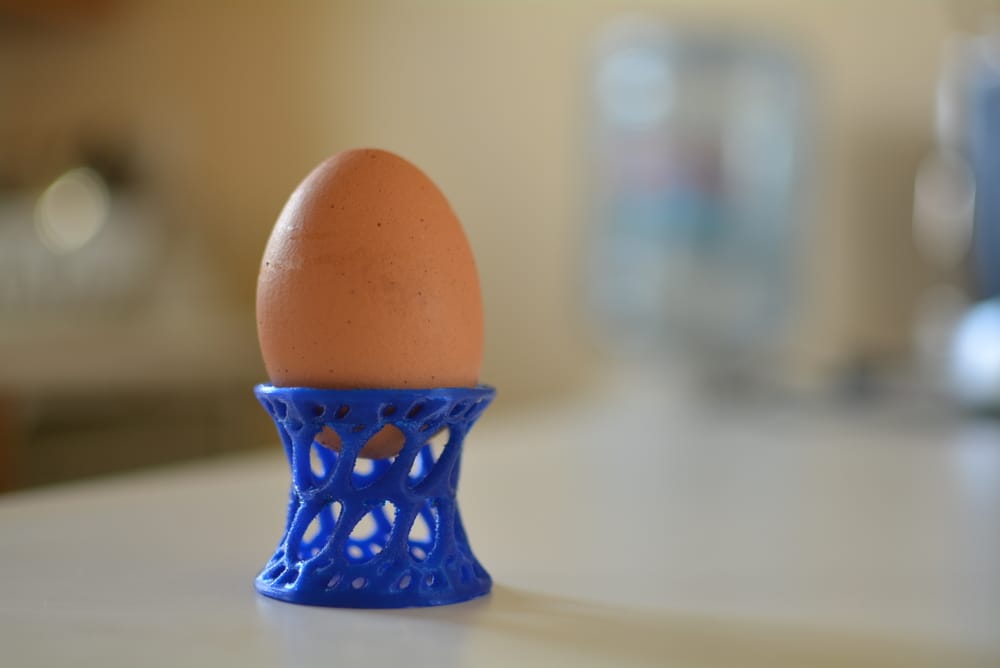

Is pla food safe – Polylactic acid (PLA) is a biodegradable and compostable plastic derived from renewable resources like corn starch or sugarcane. It has gained popularity as a sustainable alternative to traditional plastic food containers. However, concerns have been raised about the safety of PLA for food contact.

This article delves into the topic of is PLA food safe, exploring the chemical composition, manufacturing processes, potential health risks, and environmental considerations associated with PLA food containers.

We will examine the relevant food safety standards and regulations, discuss the chemical properties of PLA, and assess the potential for chemical migration and leaching from PLA food containers. We will also explore the environmental benefits and concerns associated with PLA and provide recommendations for safe use to minimize any potential risks.

Food Safety Standards and Regulations

Polylactic acid (PLA) food containers are subject to various food safety standards and regulations to ensure the safety of food products. These regulations are established by government agencies to protect consumers from potential health hazards associated with food contamination.

The U.S. Food and Drug Administration (FDA) is responsible for regulating the safety of food packaging materials, including PLA. The FDA has established specific requirements for the use of PLA in food contact applications, such as:

- PLA must meet the requirements of the FDA’s food additive regulations (21 CFR 177).

- PLA must not contain any harmful substances that could migrate into food.

- PLA must be manufactured under Good Manufacturing Practices (GMPs) to ensure its safety and quality.

Role of Government Agencies

Government agencies play a crucial role in ensuring the safety of PLA food containers. They establish and enforce food safety standards, conduct inspections of food packaging facilities, and take enforcement actions against companies that violate these regulations.

In addition to the FDA, other government agencies involved in regulating PLA food containers include:

- The U.S. Environmental Protection Agency (EPA) regulates the use of chemicals in PLA production.

- The U.S. Department of Agriculture (USDA) regulates the use of PLA in food packaging for meat and poultry products.

Specific Regulations

Here are some specific examples of regulations that govern the use of PLA in food packaging:

- 21 CFR 177.1630: This regulation establishes the conditions under which PLA can be used as a food additive.

- 21 CFR 178.3297: This regulation sets forth the specific requirements for the use of PLA in food contact applications.

- 9 CFR 318.7: This regulation establishes the USDA’s requirements for the use of PLA in food packaging for meat and poultry products.

Chemical Composition and Properties of PLA

Polylactic acid (PLA) is a biodegradable and biocompatible thermoplastic made from renewable resources such as corn starch or sugarcane. It is a linear aliphatic polyester composed of repeating units of lactic acid. The chemical structure of PLA can be represented as:

(C3H 4O 2) n

The properties of PLA make it suitable for use in food packaging. It is transparent, has good mechanical strength, and is resistant to grease and oil. PLA is also biodegradable, which means it can break down into natural components over time.

Potential Concerns or Limitations

One potential concern with PLA is that it can be brittle when exposed to high temperatures. This can make it difficult to use in applications where the material will be subjected to heat. Additionally, PLA is not as strong as some other plastics, so it may not be suitable for applications where high strength is required.

Manufacturing Processes for PLA Food Containers

The production of PLA food containers involves several key manufacturing processes, each contributing to the safety and quality of the final product.

The initial step is the extraction of lactic acid from plant-based sources, such as corn starch or sugarcane. This lactic acid is then polymerized to form polylactic acid (PLA), which is the primary material used in the manufacturing of PLA food containers.

Extrusion

Extrusion is a widely employed technique for shaping PLA into various forms, including food containers. In this process, molten PLA is forced through a die, resulting in a continuous profile that is then cut into the desired shape and size of the container.

Extrusion offers precise control over the thickness and dimensions of the container, ensuring uniformity and consistency in the final product.

Injection Molding

Injection molding is another common method for producing PLA food containers. In this process, molten PLA is injected into a mold cavity, where it takes the shape of the mold. Once cooled, the container is ejected from the mold.

Injection molding allows for the production of complex shapes and intricate designs, making it suitable for creating containers with specific features or aesthetics.

Thermoforming

Thermoforming involves heating a sheet of PLA until it becomes pliable and then molding it into the desired shape using a mold or press. This process is often used to produce containers with large surface areas, such as trays or lids.

Thermoforming offers flexibility in terms of shape and size, making it suitable for a wide range of container applications.

Potential Risks and Hazards

While PLA food containers are generally considered safe, certain risks and hazards may arise during the manufacturing process:

- Contamination:The raw materials used in PLA production, as well as the manufacturing equipment, must be carefully controlled to prevent contamination from microorganisms or chemicals.

- Residual monomers:Trace amounts of lactic acid monomers may remain in the final PLA product, which could potentially migrate into food and pose a health risk.

- Additives:Additives, such as plasticizers or colorants, may be used in the manufacturing process to enhance the properties of PLA. These additives must be carefully selected and controlled to ensure their safety and compatibility with food contact.

Adhering to strict manufacturing standards and quality control measures is crucial to minimize these risks and ensure the safety and quality of PLA food containers.

Migration and Leaching of Chemicals from PLA Food Containers: Is Pla Food Safe

Migration and leaching are processes that involve the transfer of chemicals from PLA food containers into food or beverages. Migration refers to the movement of chemicals from the container material into the food, while leaching specifically refers to the extraction of chemicals by a liquid, such as water or an acidic beverage.

Several factors can influence the migration and leaching of chemicals from PLA food containers. These include:

- Temperature:Higher temperatures generally increase the rate of migration and leaching.

- Contact time:The longer food or beverages are in contact with the PLA container, the greater the potential for migration and leaching.

- Type of food or beverage:The composition and acidity of food or beverages can affect the rate of migration and leaching. Acidic foods or beverages can promote the leaching of chemicals from PLA.

- Surface area:The larger the surface area of the PLA container that is in contact with the food or beverage, the greater the potential for migration and leaching.

- Additives and coatings:Additives and coatings used in the manufacturing of PLA containers can also affect the rate of migration and leaching.

Specific Chemicals that May Migrate or Leach from PLA Food Containers

The specific chemicals that may migrate or leach from PLA food containers can vary depending on the type of PLA used, the manufacturing process, and the conditions of use. Some examples of chemicals that have been identified as potential migrants or leachables from PLA include:

- Lactic acid

- Oligomers of lactic acid

- Residual catalysts

- Additives, such as plasticizers or antioxidants

Health and Safety Concerns

PLA food containers have gained popularity due to their biodegradable nature, but concerns have arisen regarding their potential health and safety implications.Scientific evidence has emerged both supporting and refuting these concerns. Studies have shown that PLA itself is generally recognized as safe (GRAS) by the FDA and is not known to leach harmful chemicals into food.

However, some concerns have been raised about the potential for PLA food containers to release residual monomers, such as lactic acid, during food contact.

Lactic Acid Concerns

Lactic acid is a natural byproduct of PLA production and can be present in small amounts in PLA food containers. While lactic acid is generally safe, high levels can cause stomach upset and other digestive issues. However, studies have shown that the amount of lactic acid released from PLA food containers is typically very low and unlikely to pose a health risk.

Recommendations for Safe Use

To minimize any potential risks associated with PLA food containers, the following recommendations are advised:

- Choose PLA food containers that meet industry standards and have been certified by reputable organizations.

- Avoid using PLA food containers for prolonged storage or heating of acidic or oily foods.

- Wash PLA food containers thoroughly before first use and after each use.

- Dispose of PLA food containers properly according to local regulations.

By following these recommendations, individuals can safely enjoy the benefits of PLA food containers while minimizing any potential health and safety concerns.

Environmental Considerations

The use of PLA food containers offers both environmental benefits and concerns. PLA is derived from renewable plant resources, reducing reliance on non-renewable fossil fuels. It is also biodegradable and compostable under specific conditions, potentially reducing waste in landfills.

Biodegradability and Composting, Is pla food safe

PLA is a biodegradable polymer that can break down into natural components over time. Under controlled composting conditions, such as in industrial composting facilities, PLA can decompose within a matter of months. However, the biodegradability of PLA in natural environments, such as home composting or littering, can vary depending on factors like temperature, moisture, and the presence of microorganisms.

Environmental Impact Comparison

Compared to traditional plastic food containers made from petroleum-based materials, PLA food containers generally have a lower environmental impact. They require less energy to produce and emit fewer greenhouse gases during their life cycle. Additionally, the biodegradability of PLA can reduce the accumulation of plastic waste in landfills and the environment.

FAQ Resource

Is PLA food safe?

Yes, PLA is generally considered safe for food contact. It meets the safety standards set by regulatory agencies like the FDA and EFSA.

Does PLA leach chemicals into food?

PLA has a low potential for chemical migration. However, factors like temperature, storage conditions, and food type can influence the migration rate.

Is PLA biodegradable?

Yes, PLA is biodegradable under specific conditions, such as industrial composting facilities. It breaks down into lactic acid, a natural substance found in the human body.

Is PLA compostable?

Yes, PLA is compostable in commercial composting facilities. However, backyard composting may not be effective due to slower degradation rates.