Food truck exhaust hoods play a crucial role in maintaining a safe and sanitary environment for food preparation and serving. They effectively remove cooking fumes, grease, and odors, ensuring the well-being of customers and staff alike. This comprehensive guide will delve into the design, installation, maintenance, regulations, and safety aspects of food truck exhaust hoods, providing valuable insights for food truck operators and industry professionals.

Exhaust Hood Overview

Exhaust hood systems are an essential part of commercial kitchens, as they help to remove smoke, grease, and other pollutants from the air. They are typically located above cooking appliances, such as stoves, ovens, and grills.

The purpose of an exhaust hood is to capture and remove airborne contaminants before they can spread throughout the kitchen. This helps to improve the air quality for employees and customers, and it can also help to prevent the buildup of grease and other residues on surfaces.

Components of an Exhaust Hood

Exhaust hoods are typically made up of the following components:

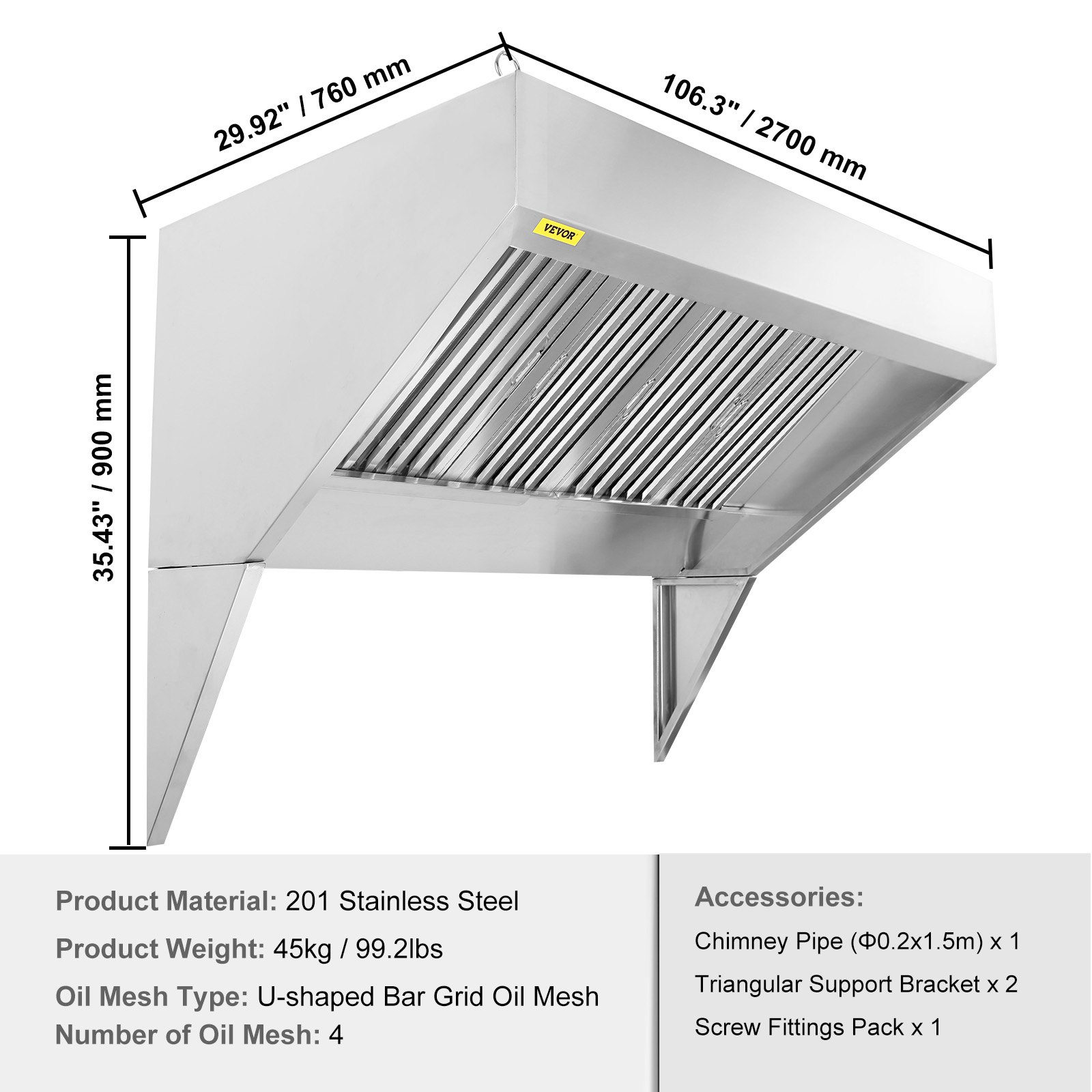

- Hood body: The hood body is the main part of the exhaust hood. It is typically made of stainless steel or aluminum, and it is designed to capture and contain airborne contaminants.

- Baffles: Baffles are located inside the hood body, and they help to separate grease and other particles from the air. Baffles can be made of a variety of materials, such as stainless steel, aluminum, or plastic.

- Filters: Filters are located at the top of the hood body, and they help to remove smaller particles from the air. Filters can be made of a variety of materials, such as paper, cloth, or metal.

- Exhaust fan: The exhaust fan is located at the top of the hood body, and it helps to draw air through the hood and expel it outside. Exhaust fans can be powered by electricity or gas.

Food Truck Exhaust Hood Design

The design of a food truck exhaust hood is crucial for ensuring proper ventilation and maintaining a safe and healthy environment within the truck. Several factors influence hood design, and it’s essential to consider these factors to achieve an efficient and effective exhaust system.

Factors Influencing Hood Design

- Truck Size and Layout:The size and layout of the food truck determine the required hood size and shape.

- Cooking Equipment:The type and quantity of cooking equipment used will impact the amount of heat and grease produced, which affects hood capacity.

- Ventilation Requirements:Local codes and regulations specify the minimum ventilation rates required for food trucks.

- Grease Removal:The hood must be designed to effectively capture and remove grease from the air.

Efficient Exhaust Hood Designs

Efficient exhaust hood designs incorporate features that enhance ventilation and grease removal. Some examples include:

- Sloped Hood:A sloped hood helps grease drain away from the cooking surface.

- Baffle Filters:Baffle filters trap grease particles before they enter the ductwork.

- High-Efficiency Fans:High-efficiency fans provide strong airflow to effectively remove heat and grease.

- Makeup Air Systems:Makeup air systems replace the air exhausted by the hood, ensuring proper ventilation and preventing negative air pressure.

Exhaust Hood Installation and Maintenance

Installing an exhaust hood on a food truck involves several steps:1.

-

-*Planning and Design

Determine the hood’s size, location, and ventilation requirements based on the truck’s cooking equipment and layout.

- 2.

- 3.

- 4.

- 5.

-*Mounting

Secure the hood to the truck’s roof or sidewall using appropriate brackets and fasteners.

-*Ductwork

Install ductwork to connect the hood to the truck’s ventilation system, ensuring proper airflow and exhaust.

-*Electrical Wiring

Connect the hood’s electrical components, such as fans and lighting, to the truck’s electrical system.

-*Testing and Commissioning

Test the hood’s operation, including fan speed, airflow, and grease filtration efficiency.

Regular maintenance is crucial for ensuring proper operation and safety of exhaust hoods:

-

-*Cleaning

Regularly clean the hood’s filters, grease traps, and ductwork to remove grease buildup and prevent fire hazards.

-*Inspection

Inspect the hood for any damage, corrosion, or loose components, and repair or replace as needed.

-*Filter Replacement

Replace grease filters according to the manufacturer’s recommendations or when they become saturated.

-*Fan Maintenance

Ensure fans are operating properly and lubricate bearings as needed.

Proper ventilation and airflow are essential for effective exhaust hood operation:

-

-*Airflow

The hood should be designed to provide sufficient airflow to capture and remove cooking fumes, smoke, and heat from the cooking area.

-*Exhaust System

The ventilation system should be designed to exhaust the captured air outside the truck, preventing recirculation and potential health hazards.

-*Makeup Air

Makeup air units may be required to replace the air exhausted by the hood, ensuring proper indoor air quality and preventing negative pressure.

Exhaust Hood Regulations and Safety: Food Truck Exhaust Hood

Exhaust hoods play a critical role in maintaining a safe and healthy environment in commercial kitchens. They remove smoke, grease, and other airborne contaminants, ensuring that the air is clean and free from hazards. However, it is essential to adhere to specific regulations and safety guidelines to ensure the proper operation and maintenance of exhaust hoods.

Regulations

The regulations governing exhaust hood systems in the food industry vary depending on the jurisdiction. However, some common requirements include:

- Exhaust hoods must be designed and installed to meet the specific needs of the kitchen.

- Exhaust hoods must be regularly inspected and cleaned to ensure proper operation.

- Exhaust hoods must be equipped with fire suppression systems to prevent the spread of fire.

Safety Hazards

Exhaust hoods can pose several safety hazards if not properly maintained. These hazards include:

- Fire:Grease buildup on exhaust hoods can create a fire hazard if it ignites.

- Carbon monoxide poisoning:Exhaust hoods that are not properly vented can allow carbon monoxide to build up in the kitchen, leading to poisoning.

- Respiratory problems:Smoke and other airborne contaminants can irritate the lungs and cause respiratory problems if they are not removed from the kitchen.

Safe Operation, Food truck exhaust hood

To ensure the safe operation of exhaust hoods, it is important to:

- Keep exhaust hoods clean and free of grease buildup.

- Inspect exhaust hoods regularly for any damage or malfunction.

- Have exhaust hoods serviced by a qualified technician at least once a year.

- Train employees on the proper use and maintenance of exhaust hoods.

By following these regulations and safety guidelines, you can ensure that your exhaust hood system is operating safely and effectively, protecting your employees and customers from potential hazards.

Exhaust Hood Troubleshooting

Exhaust hoods are essential for maintaining a clean and safe work environment in food trucks. However, like any other equipment, they can occasionally experience problems. It is crucial to be aware of common issues and troubleshooting tips to ensure optimal performance and prevent potential hazards.

Regular inspections and repairs are also essential to extend the lifespan of the exhaust hood and maintain its efficiency. By following these troubleshooting guidelines, food truck operators can keep their exhaust hoods functioning properly and ensure a healthy and comfortable cooking space.

Identifying Common Problems

- Insufficient Ventilation:Weak or nonexistent airflow can indicate a clogged filter, blocked ductwork, or an undersized exhaust fan.

- Excessive Noise:Unusual noises, such as rattling or humming, may indicate loose components, worn bearings, or an unbalanced fan.

- Grease Buildup:Grease accumulation on the hood, filters, or ductwork can reduce airflow and increase the risk of fire.

- Electrical Faults:Electrical issues, such as flickering lights or tripped breakers, can be caused by faulty wiring, loose connections, or a damaged motor.

- Filter Damage:Torn or damaged filters can allow grease and smoke to escape, reducing ventilation efficiency.

Troubleshooting Tips

- Clean or Replace Filters:Clogged filters restrict airflow. Clean or replace filters regularly to maintain optimal ventilation.

- Inspect Ductwork:Blockages in ductwork can impede airflow. Inspect ductwork for obstructions and remove any debris or grease buildup.

- Check Fan Size:An undersized exhaust fan may not provide sufficient ventilation. Consult with a professional to determine the appropriate fan size for your food truck.

- Tighten Loose Components:Loose components can cause excessive noise. Tighten any loose bolts, screws, or brackets to eliminate vibrations.

- Lubricate Bearings:Worn bearings can also cause noise. Lubricate bearings regularly to reduce friction and prevent premature failure.

- Inspect Electrical Connections:Electrical faults can be hazardous. Inspect electrical connections for loose wires, damaged insulation, or corrosion. Contact a qualified electrician for repairs.

- Replace Damaged Filters:Torn or damaged filters compromise ventilation efficiency. Replace damaged filters promptly to maintain proper airflow.

Importance of Regular Inspections and Repairs

Regular inspections and repairs are crucial for maintaining the health and safety of food truck operators and customers. By addressing issues early on, you can prevent minor problems from escalating into major repairs or potential hazards.

Inspections should include checking for grease buildup, filter damage, loose components, and electrical faults. Repairs should be performed by qualified technicians to ensure the exhaust hood operates safely and efficiently.

Helpful Answers

What are the key design considerations for food truck exhaust hoods?

The design of food truck exhaust hoods should prioritize efficient fume and grease removal, considering factors such as hood size, shape, airflow capacity, and placement relative to cooking appliances.

How often should food truck exhaust hoods be inspected and cleaned?

Regular inspections and cleaning are crucial to maintain the effectiveness of exhaust hoods. Inspections should be conducted monthly, while thorough cleaning is recommended every 3-6 months or more frequently depending on usage.

What safety precautions should be taken when operating food truck exhaust hoods?

Safety measures include ensuring proper ventilation, avoiding flammable materials near the hood, keeping the hood free of grease buildup, and having a fire suppression system in place.